Mercedes panel sectioning is a revolutionary technique for automotive body restoration, dividing complex vehicle panels into manageable sections for efficient repair and replacement. This innovative approach significantly reduces costs, cuts labor time, and minimizes material waste compared to traditional methods. By focusing on individual damaged panels, restorers can deliver high-quality results within tight budgets, ensuring structural integrity and revitalizing both the vehicle's structure and appearance.

Mercedes panel sectioning is revolutionizing structural restoration, offering a cost-effective solution for old or damaged buildings. This innovative technique involves carefully cutting and removing sections of a structure, replacing them with new, pre-fabricated panels. By utilizing Mercedes panel sectioning, restorers can preserve historical integrity while significantly reducing time and labor costs. Discover the benefits and process behind this game-changing approach to restoration.

- Understanding Mercedes Panel Sectioning: A Revolutionary Approach to Structural Restoration

- Benefits of Using Mercedes Panel Sectioning for Cost-Effective Restorations

- The Process: How Mercedes Panel Sectioning Transforms Old Structures into New

Understanding Mercedes Panel Sectioning: A Revolutionary Approach to Structural Restoration

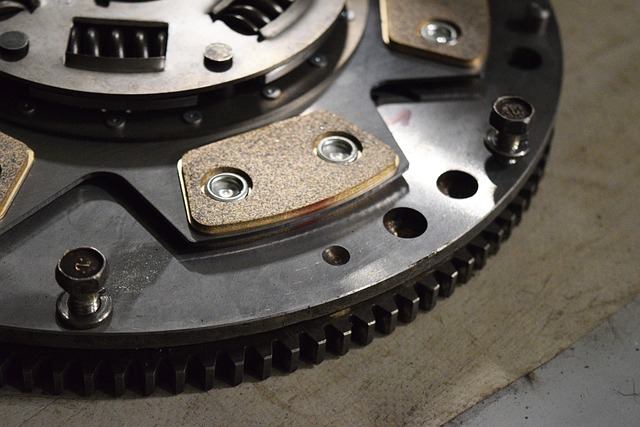

Mercedes panel sectioning represents a revolutionary approach to structural restoration in both automotive body shops and beyond. This innovative technique involves breaking down complex vehicle panels into smaller, manageable sections, allowing for precise repair and replacement. By focusing on individual components rather than entire panels, auto dent repair professionals can significantly reduce costs associated with traditional restoration methods.

This method is particularly beneficial for auto repair services, as it streamlines the process, minimizing labor-intensive tasks and maximizing efficiency. As a result, vehicle owners enjoy faster turnaround times and more affordable pricing without compromising on quality. Mercedes panel sectioning exemplifies how modern technology can transform age-old practices, ensuring that damaged vehicles are restored to their former glory while maintaining economic viability.

Benefits of Using Mercedes Panel Sectioning for Cost-Effective Restorations

Mercedes panel sectioning offers a host of benefits for cost-effective structural restoration projects. By utilizing pre-fabricated panels, restorers can significantly reduce labour costs and repair times compared to traditional methods. This is particularly advantageous in the auto collision repair sector, where efficient and accurate repairs are crucial. The precision manufacturing process ensures that Mercedes panel sectioning fits seamlessly, minimizing the need for additional auto glass repair or vehicle dent repair work.

Moreover, this innovative approach streamlines the restoration process, making it more accessible and affordable. It allows for quick replacement of damaged sections without having to replace entire panels, which is both eco-friendly and economical. In a bustling market where every dollar counts, Mercedes panel sectioning stands out as a game-changer in auto collision repair, enabling restorers to deliver high-quality results while maintaining tight budgets.

The Process: How Mercedes Panel Sectioning Transforms Old Structures into New

Mercedes panel sectioning is a revolutionary process that transforms aged structures into like-new conditions with remarkable efficiency and affordability. It involves carefully detaching and replacing damaged or degraded car bodywork panels, rather than repairing or reconstructing entire sections of a vehicle. This method leverages advanced manufacturing techniques to create precision-engineered replacement parts, ensuring exact fitment and structural integrity.

By sectioning off problematic areas, auto bodyworkers can focus their efforts where it’s needed most, minimizing waste and labor costs. The process begins with the removal of the damaged panel, followed by a thorough inspection to determine the extent of repair or replacement required. Once assessed, new panels are custom-fabricated using advanced materials and technologies, matching the original specifications of the car bodywork services precisely. These freshly minted panels are then seamlessly installed, revitalizing the vehicle’s structural integrity and aesthetic appeal.

Mercedes panel sectioning stands as a game-changer in structural restoration, offering cost-effective solutions without compromising quality. By utilizing this innovative approach, old structures can be transformed into new ones with precision and efficiency. Through its benefits and meticulous process, Mercedes panel sectioning ensures that historic buildings and landmarks can be preserved while meeting modern standards, making it an invaluable tool for restoration projects worldwide.